Batteries Not Included: 3D Printed Plastic Objects Talk Via Ambient Wi-Fi

By Jof Enriquez,

Follow me on Twitter @jofenriq

University of Washington engineers have 3D-printed plastic objects that do not require batteries or electronics to transmit data to other devices. Instead, these objects ‘talk’ to each other using embedded antennas that reflect ambient radio signals.

The UW team has been experimenting with backscattering methods to reflect FM radio signals, and demonstrated earlier this year the transmission of a snippet of a band’s music off a poster at a bus stop to a nearby smartphone. The demonstration showed how ubiquitous radio signals already present in the air can allow everyday objects to exchange information without the need for batteries or electronics.

In another first, the researchers demonstrated more recently how to 3D-print these objects using commercially available plastics and commodity desktop 3D printers, and how to connect them with low or zero power requirements.

“Our goal was to create something that just comes out of your 3D printer at home and can send useful information to other devices,” said co-lead author and UW electrical engineering doctoral student Vikram Iyer. “But the big challenge is how do you communicate wirelessly with Wi-Fi using only plastic? That’s something that no one has been able to do before.”

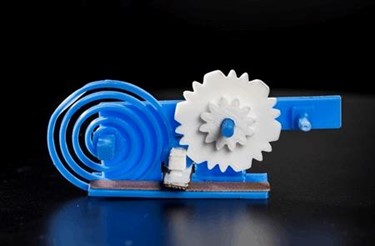

In lieu of electronic components, the team 3D-printed springs, gears, and switches. Moving in tandem, these components work similarly to the parts of a mechanical watch, which harness motion to keep time. In the team’s prototypes, the springs and gears are designed to toggle a switch made of conductive printing filament that mixes plastic with copper.

Then, “Physical motion — pushing a button, laundry soap flowing out of a bottle, turning a knob, removing a hammer from a weighted tool bench — triggers gears and springs elsewhere in the 3-D printed object that cause a conductive switch to intermittently connect or disconnect with the antenna and change its reflective state.” In turn, this conveys useful data to a WiFi receiver.

One object they 3D-printed was a plastic attachment to a laundry bottle.

“As you pour detergent out of a Tide bottle, for instance, the speed at which the gears are turning tells you how much soap is flowing out. The interaction between the 3-D printed switch and antenna wirelessly transmits that data,” said senior author Shyam Gollakota, an associate professor in the Paul G. Allen School of Computer Science & Engineering. “Then the receiver can track how much detergent you have left and when it dips below a certain amount, it can automatically send a message to your Amazon app to order more.”

Besides the 'smart' detergent bottle, the team also created 3D printed buttons that automatically make online orders, as well as smart sliders and physical knobs that wirelessly control music volume and lights. They also presented designs for 3D printed wireless sensors, including a weight scale, flow sensor/meter, and anemometer that can transmit sensor data.

Using a different type of 3D printing filament that combines plastic with iron (instead of copper), the team also was able to embed data within objects using magnetic fields, and decode the data using magnetometers on commercial smartphones. The static data could range from barcode identification for inventory tracking, or information about the object useful for a robot interacting with it, according to Futurity.

"It looks like a regular 3D-printed object but there's invisible information inside that can be read with your smartphone," said Justin Chan, another student on the project, reports Engadget.

Shyamnath Gollakota joins Iyer and Chan as co-authors of the paper presented Nov. 30 at the Association for Computing Machinery’s SIGGRAPH Conference and Exhibition on Computer Graphics and Interactive Techniques in Asia.

They are making CAD models of their ‘Printed Wi-Fi’ objects available to the public.